The high-temperature fan at the kiln tail is mainly used to maintain the air circulation at the kiln tail, control exhaust gas emissions, and recover heat energy. Its specific functions are as follows:

1. Maintain system negative pressure and airflow balance

By extracting the high-temperature exhaust gas (containing dust, SO₂, etc.) generated by the kiln tail preheater and decomposition furnace, the system's negative pressure is ensured to be stable (usually -200~-500Pa), preventing positive pressure from causing exhaust gas backflow or equipment blockage.

It works in conjunction with the kiln exhaust fan to form a stable air circulation, ensuring the continuity of raw material decomposition and clinker calcination.

2. Heat recovery and waste heat power generation

High-temperature exhaust gas (300-400°C) is introduced into the waste heat boiler (SP boiler), which generates steam through heat exchange to drive the generator set, thereby improving energy utilization.

Optimizing fan speed can increase exhaust gas temperature and thus increase waste heat power generation (for example, in one case, coal consumption was reduced by 14 kg/t).

3. Combustion support and combustion control

Provide secondary air (containing oxygen) to the decomposition furnace to promote the complete combustion of fuel (coal powder) and reduce chemical incomplete combustion losses.

The temperature at the kiln tail can be controlled by adjusting the air volume (e.g., the first stage tube outlet temperature is 280-400°C) to avoid excessive NOx generation.

4. Equipment protection and energy-saving optimization

Prevent crusting or material accumulation in the kiln tail smoke chamber and reduce the risk of blockage by stabilizing the airflow.

Adopt frequency conversion technology or model predictive control (MPC) to optimize operating parameters and reduce power consumption (for example, the overall power consumption of clinker is reduced by 4 kWh/t).

The high-temperature fan at the end of the kiln is generally installed between the preheater and the decomposition furnace. If the air volume of the high-temperature fan at the end of the kiln is insufficient, the CO content in the decomposition furnace will increase, the risk of material collapse will increase, and directly affect the clinker production and quality. In addition, air leakage problems will significantly increase power consumption (for example, an air leakage rate of 13.63% will result in an annual loss of 660,000 yuan).

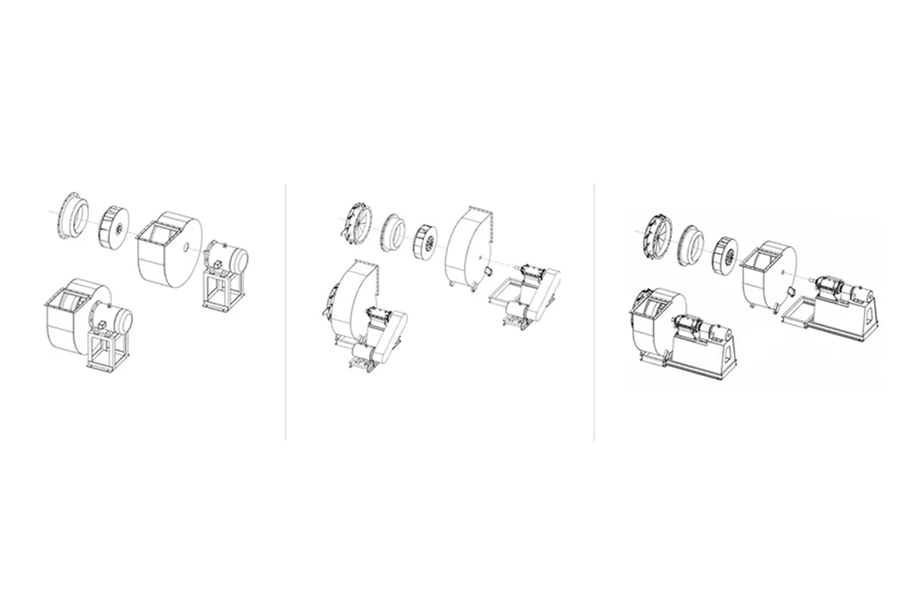

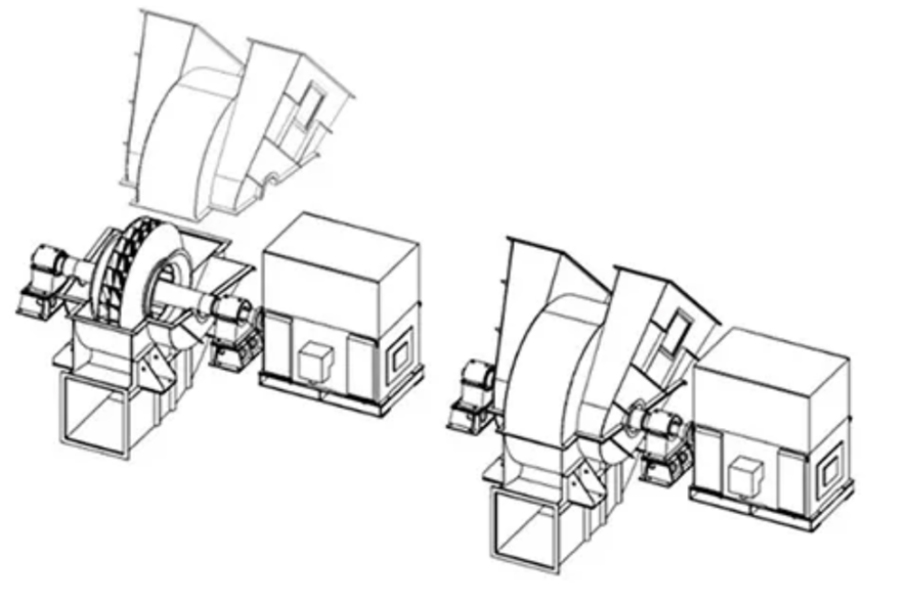

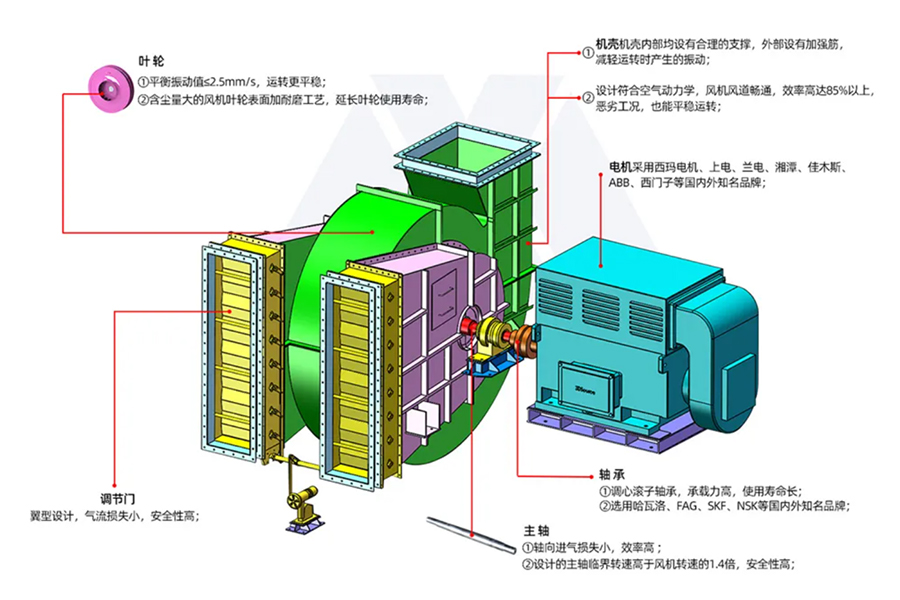

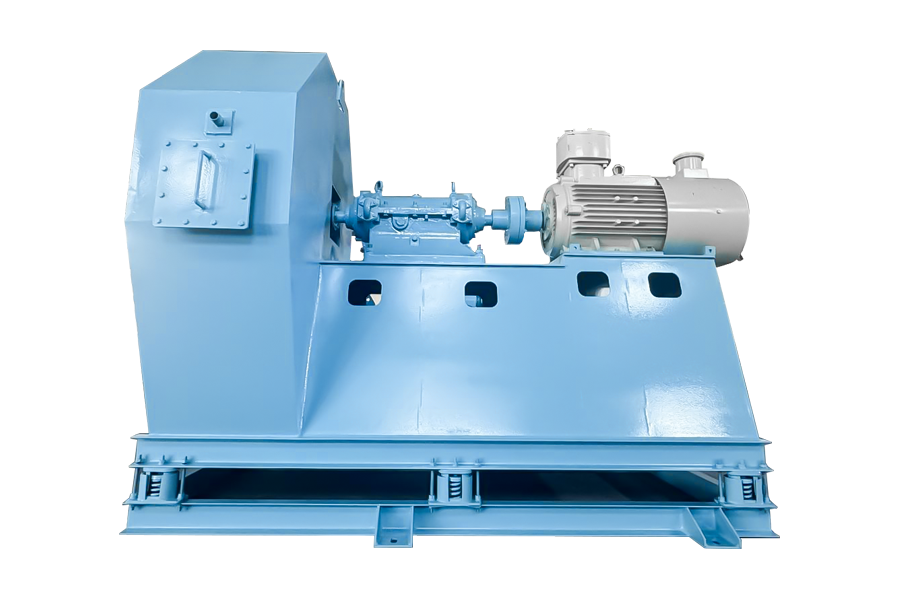

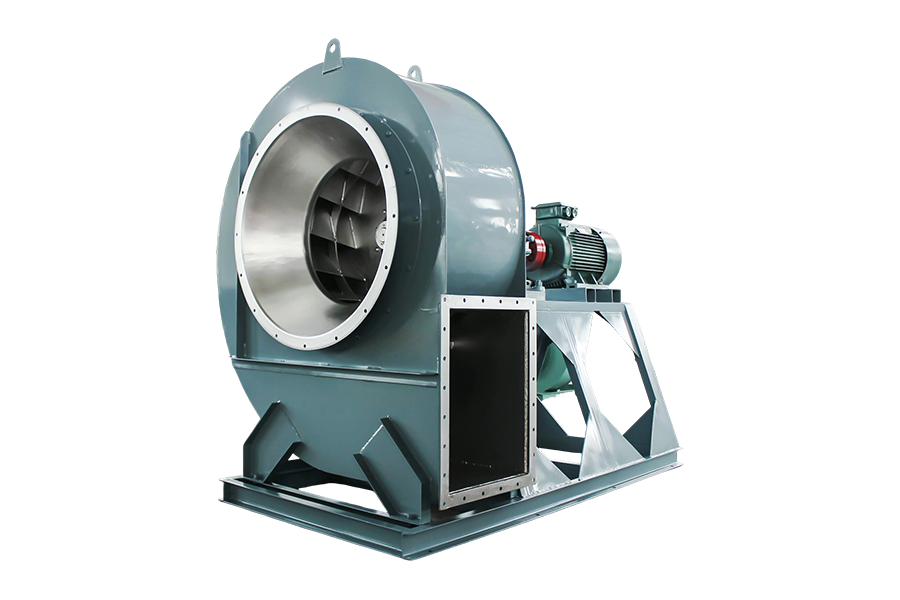

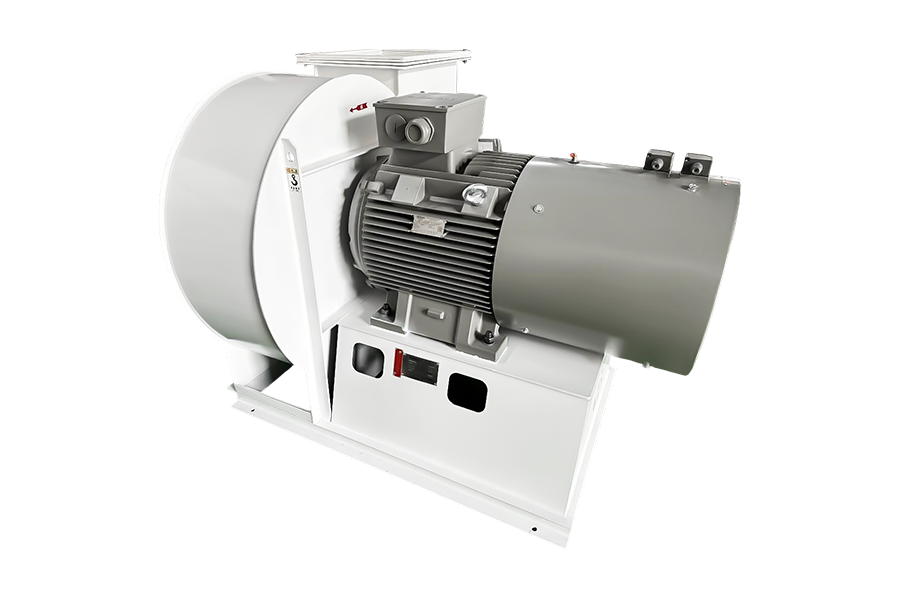

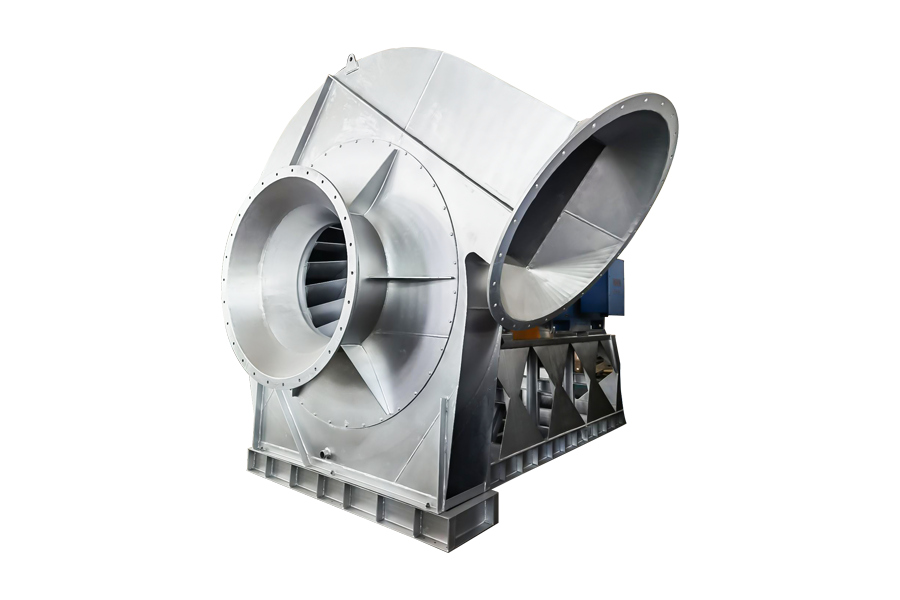

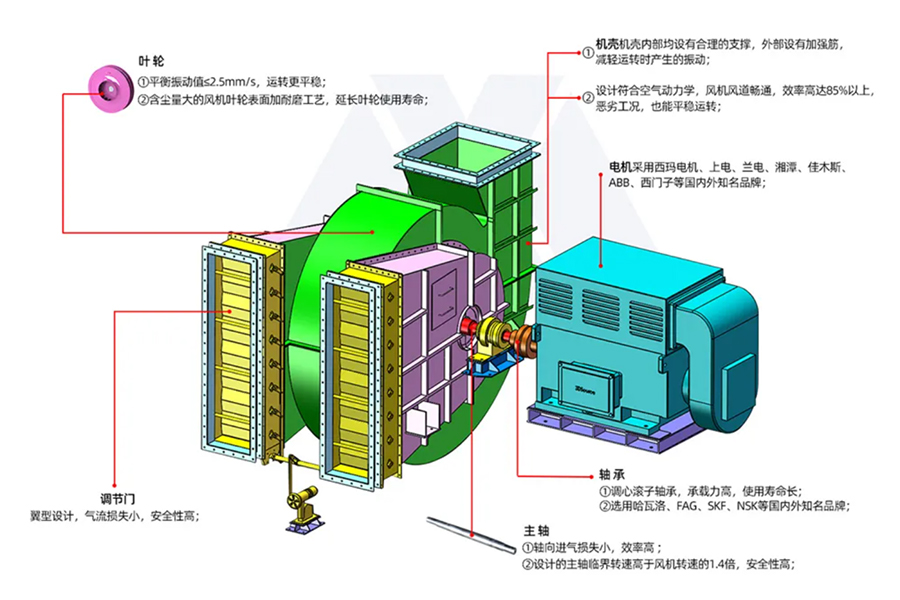

This series of fans has the characteristics of smooth operation, high strength, and long service life. This series of products has a compact design, convenient installation and commissioning, easy disassembly and maintenance, reliable operation, wear resistance, high temperature resistance, high efficiency, low noise, flat performance curve, large flow adjustment range, and a wide effective area.

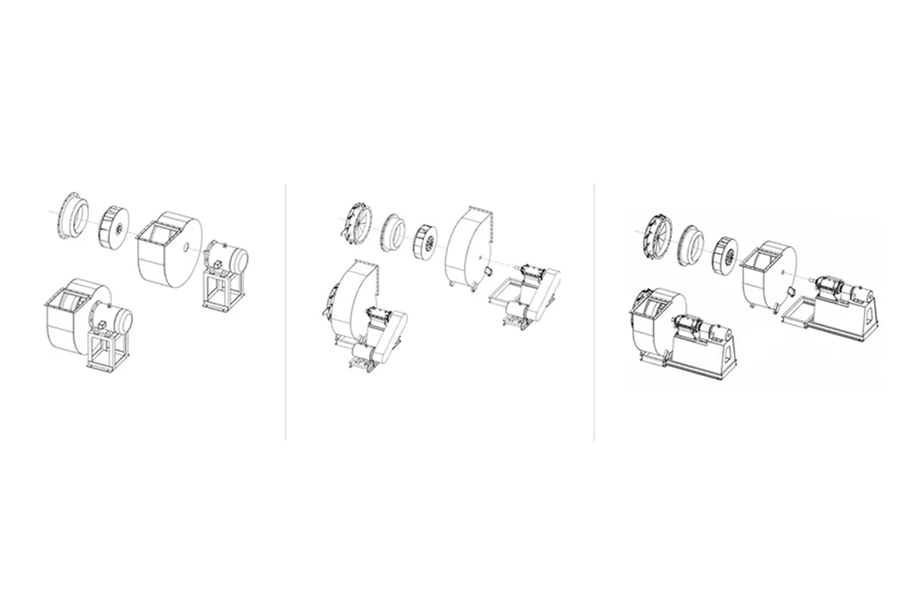

| Product Structure |

|

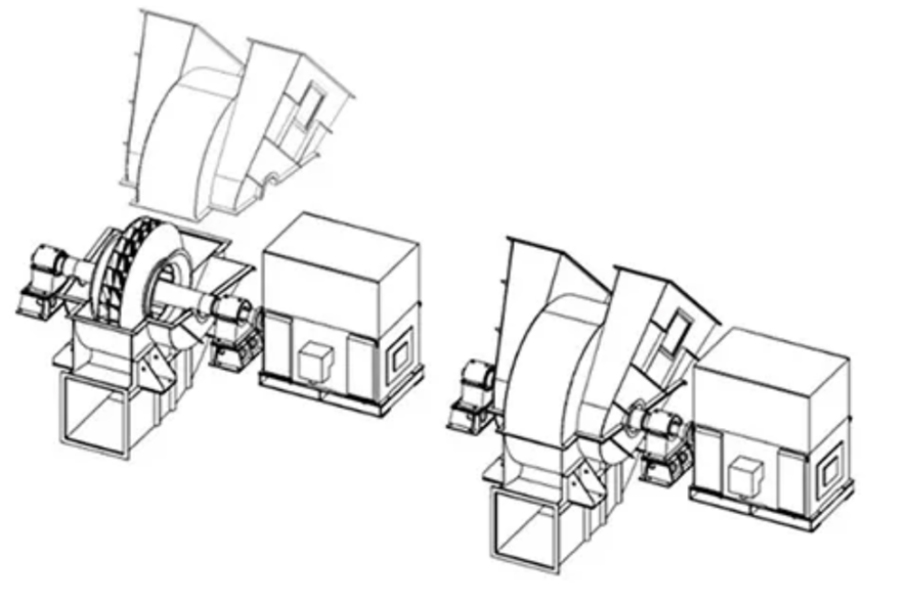

|

| Actual picture |

|

|

Contact Us

Contact Us

Language

Language

English

English русский

русский Español

Español