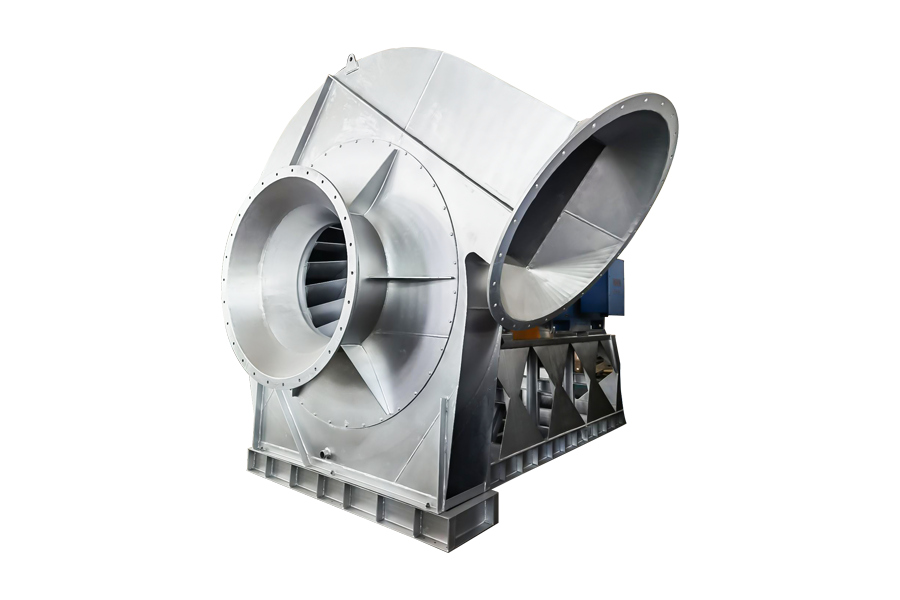

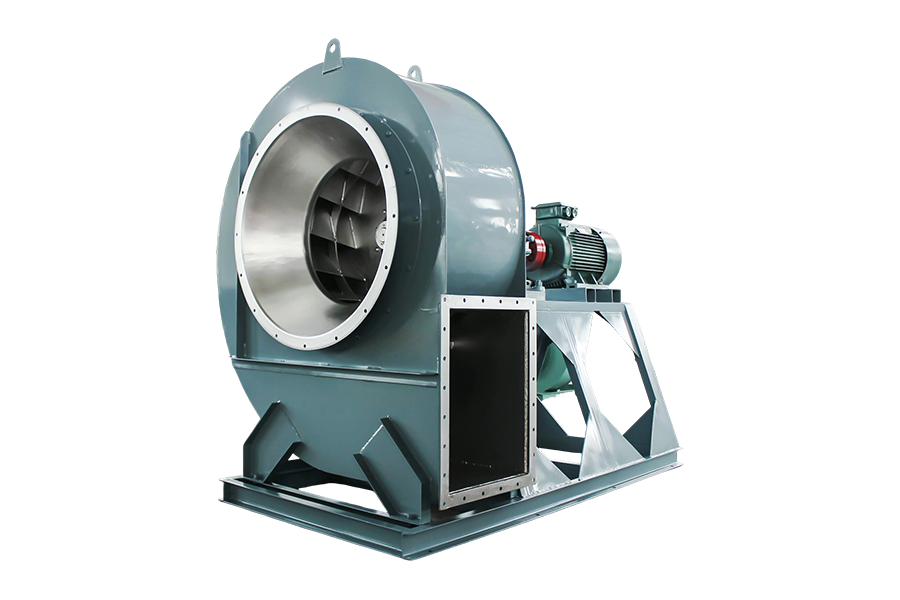

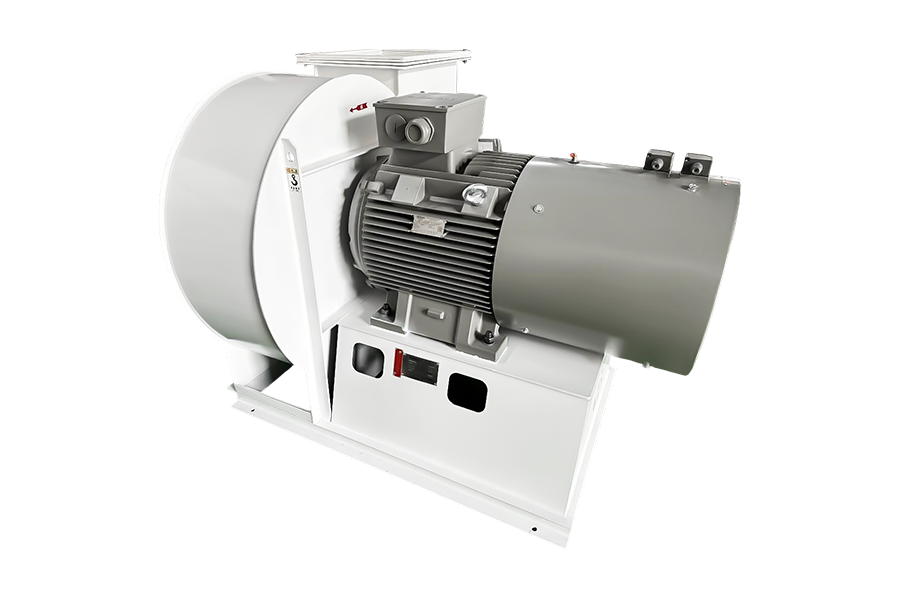

Jiangsu ZT Fan Co., Ltd., established in 1990, is a professional centrifugal fan manufacturing company that integrates research and development, design, production, sales, and after-sales service.

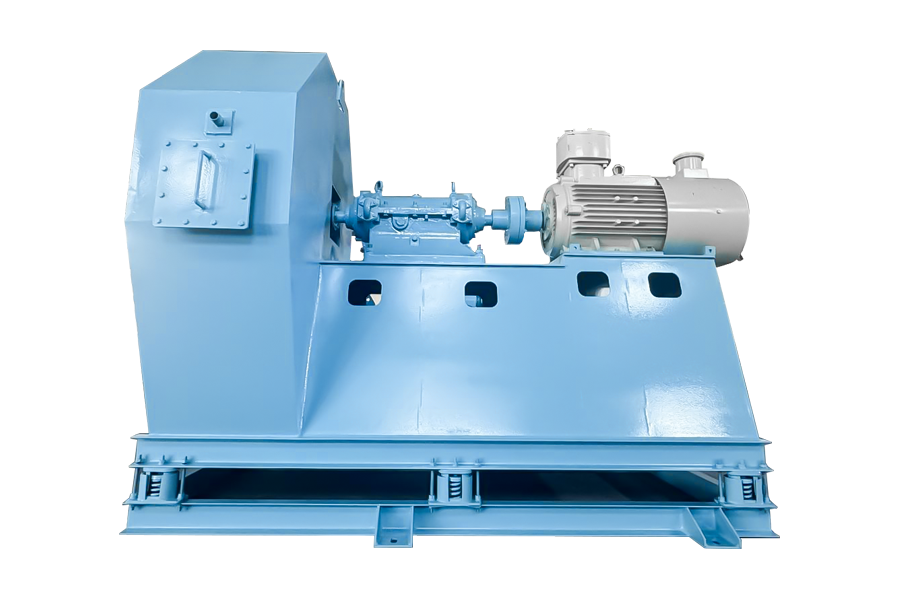

Our centrifugal fans are widely used in factory exhaust treatment systems, dust collectors, VOC treatment in paint booth or coating line, waste liquid incineration systems, solid waste incineration systems, lithium battery negative electrode material production lines, pharmaceutical companies' waste disposal systems, chemical enterprises' pollutant emission treatment systems, as well as power plants, steel mills, and metal smelting industries.

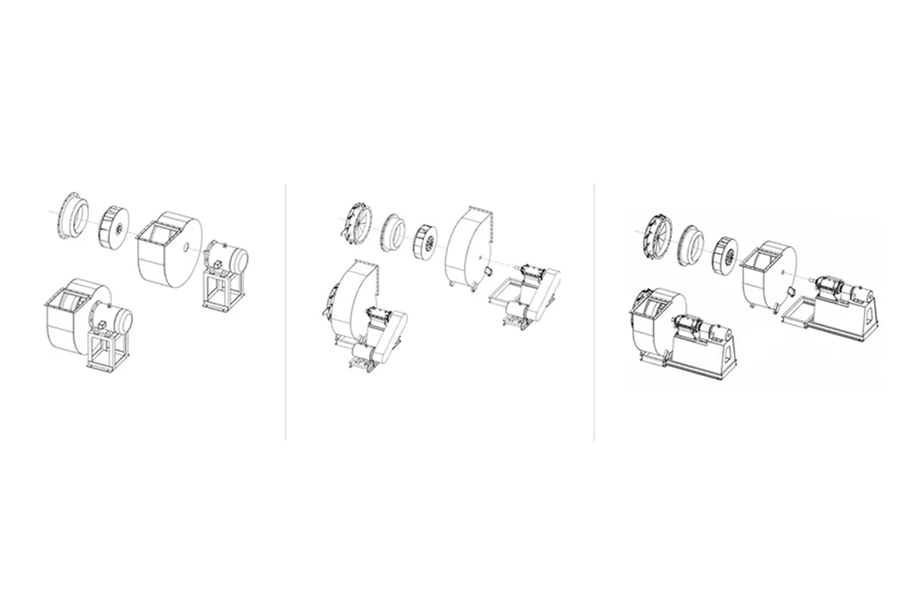

The original components of our centrifugal fans are all from well-known domestic and international brands, ensuring stable operation and extremely low failure rates. First-class design and sheet metal craftsmanship make our products aesthetically pleasing, sturdy, and durable.

We can provide customized services according to customer requirements to ensure perfect matching of centrifugal fans with user equipment. Each fan undergoes comprehensive inspection standards to ensure safe and reliable use by customers.

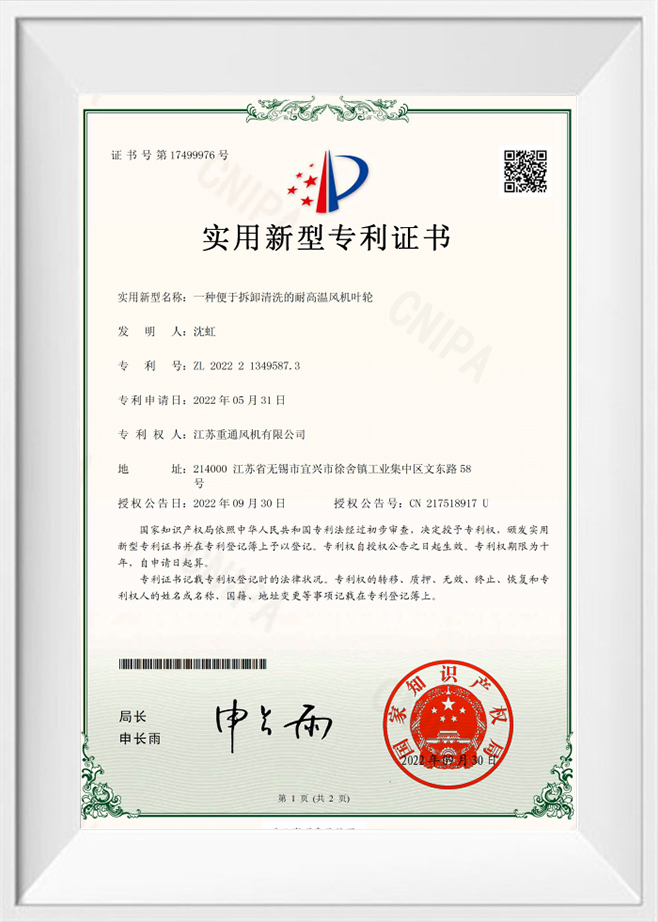

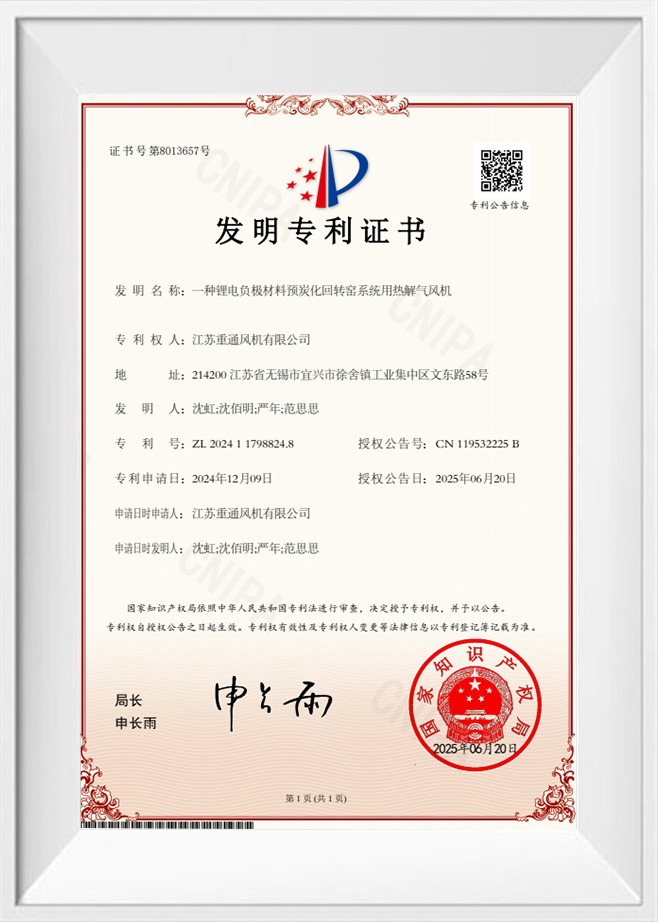

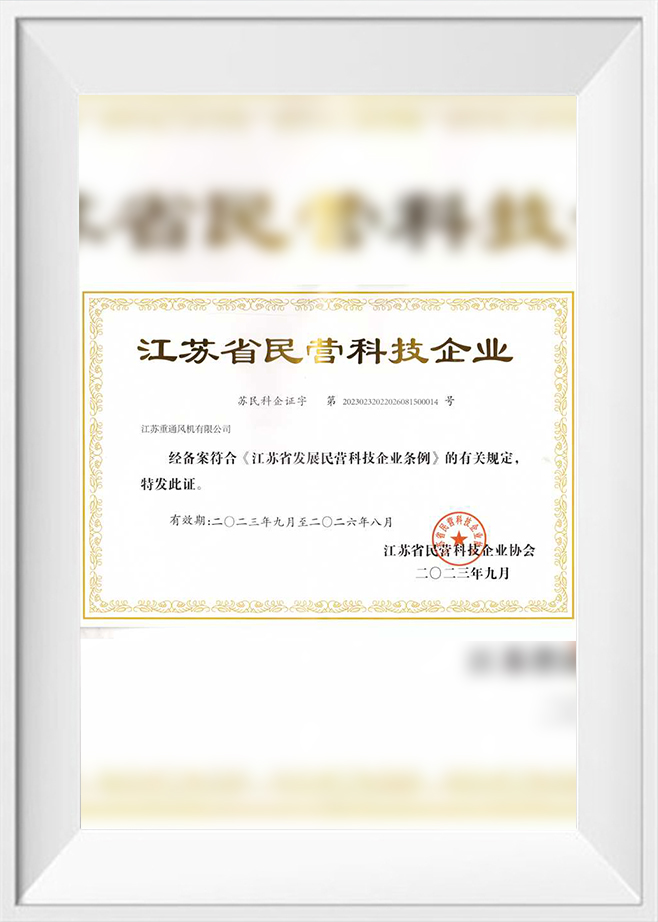

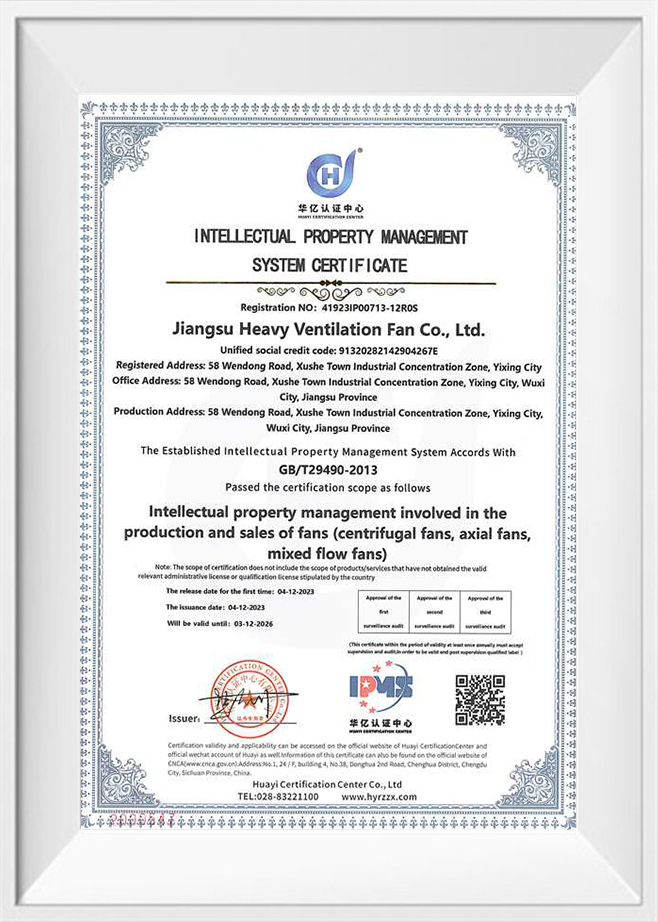

ZT FAN adheres to the corporate philosophy of 'Quality First, Integrity Above All' and always prioritizes technological innovation to continuously improve product quality, providing professional solutions for global users.

Contact Us

Contact Us

Language

Language

English

English русский

русский Español

Español